PIPE CLAMP WITH NUT

| SIZE |

BREAKING LOAD (KN) |

RECOMMENDED LOAD (KN) |

|---|---|---|

| 1/8" - 1" | 3,9 | 1,3 |

| 1 1/4" - 2" | 4,8 | 1,6 |

| 67-77 - 4" | 6,9 | 2,3 |

| 122-135 - 8" | 7,8 | 2,6 |

PLACE OF USAGE

-- This type of pipe clamps are used for the vertical and horizontal piping systems to the walls, ceilings and floors by using the hanging products such as rods, nuts, washers, anchors, sliding hinges, sliding guides etc.

-- Durability is increased with its engineered structure.

-- Safe and easy pipe clamp lip connection is enabled by the cross-recessed screw combi and hexagonal connection screws.

-- Plastic washers on the pipe clamps provide to avoid any screw lost during the assembly and transportation to the application field.

-- Pipe clamps are coated by electro-zinc galvanize with 8-12 micron.

-- EPDM rubber provides to reduce the noise and the vibration in the environment with its EPDM rubbered versions. This noise reduction is 15Db according to DIN 4109. EPDM rubber allows to reduce the vibrations and absorb properly.

-- The working temperature range of EPDM rubber is between -40 °C and +120 °C.

-- Standard metric and conical nuts are used for the hanger connection. These type of nuts have been researched and developed by NORM FIXING’s know-how and NORM FIXING developed its suppliers accordingly.

-- Nuts are welded with spot-welding and pipe clamps are tested and checked by the tensile strength test machine regularly.

-- Pipe clamps can be checked with synonym in different areas as Rohrschelle, Collier, Braçadeira de tubo, хомут and if you have any additional questions regarding the pipe clamps, please do not hesitate to contact with us.

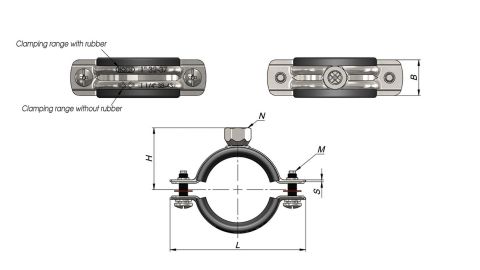

| CODE | SIZE | CLAMPING RANGE | L | H | M | SxB | N | QUATITY PER BOX | WEIGHT PER BOX |

|---|---|---|---|---|---|---|---|---|---|

| (mm) | (mm) | (mm) | (mm) | (Average kg) | |||||

| NSC006 | 1/8'' | 9 - 12 | 52,1 | 22,5 | M5 | 1x20 | M8 | 300 | 10,990 |

| NSC008 | 1/4" | 13 - 20 | 54,5 | 24 | M5 | 1x20 | M8 | 250 | 9,470 |

| NSC010 | 3/8" | 17 - 23 | 58,5 | 26 | M5 | 1x20 | M8 | 250 | 10,350 |

| NSC015 | 1/2" | 21 - 26 | 62,5 | 28 | M5 | 1x20 | M8 | 200 | 8,560 |

| NSC020 | 3/4" | 26 - 30 | 68,5 | 31 | M5 | 1x20 | M8 | 150 | 7,200 |

| NSC025 | 1" | 33 - 37 | 76 | 34,5 | M5 | 1x20 | M8 | 150 | 8,020 |

| NSC032 | 1 1/4" | 40 - 46 | 91,5 | 39 | M5 | 1,2x20 | M8 | 100 | 6,680 |

| NSC040 | 1 1/2" | 48 - 53 | 99 | 42,5 | M5 | 1,2x20 | M8 | 75 | 5,610 |

| NSC047 | 53-59 | 53 - 59 | 105 | 45,5 | M5 | 1,2x20 | M8 | 75 | 5,860 |

| NSC050 | 2" | 60 - 66 | 112 | 49 | M5 | 1,2x20 | M8 | 50 | 4,290 |

| NSC060 | 67-77 | 67 - 77 | 126 | 56 | M6 | 1,5x25 | M10 | 40 | 5,680 |

| NSC065 | 2 1/2" | 75 - 84 | 134 | 60 | M6 | 1,5x25 | M10 | 40 | 6,030 |

| NSC075 | 83-93 | 83 - 93 | 142 | 64 | M6 | 1,5x25 | M10 | 40 | 6,440 |

| NSC080 | 3" | 87 - 96 | 145 | 65,5 | M6 | 1,5x25 | M10 | 40 | 6,610 |

| NSC085 | 94-104 | 94 - 104 | 153 | 69,5 | M6 | 1,5x25 | M10 | 30 | 5,300 |

| NSC095 | 102-111 | 102 - 111 | 161 | 73,5 | M6 | 1,5x25 | M10 | 40 | 7,500 |

| NSC100 | 4" | 109 - 119 | 170 | 78 | M6 | 1,5x25 | M10 | 30 | 5,880 |

| NSC110 | 122-135 | 122 - 135 | 184 | 84,5 | M6 | 2x25 | M10 | 30 | 7,800 |

| NSC120 | 128-139 | 128 - 139 | 190 | 87,5 | M6 | 2x25 | M10 | 30 | 7,930 |

| NSC125 | 5" | 135 - 148 | 197 | 91 | M6 | 2x25 | M10 | 25 | 6,980 |

| NSC140 | 151-164 | 151 - 164 | 213 | 99 | M6 | 2x25 | M10 | 25 | 7,550 |

| NSC150 | 6" | 158 - 170 | 222 | 103,5 | M6 | 2x25 | M10 | 20 | 6,300 |

| NSC180 | 194-205 | 194 - 205 | 257 | 121 | M6 | 2x25 | M12 | 15 | 5,650 |

| NSC200 | 8" | 214 - 224 | 272 | 130 | M6 | 2x25 | M12 | 15 | 6,000 |